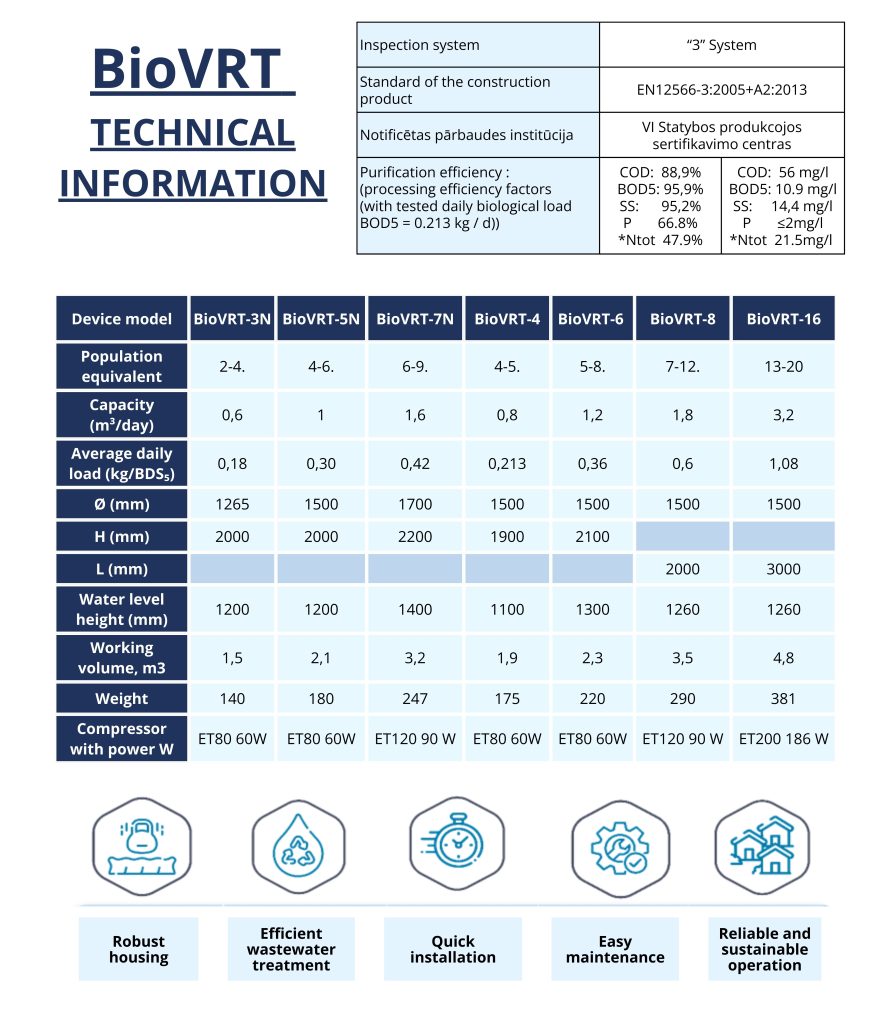

BIOLOGICAL WASTEWATER TREATMENT PLANTS

Biological treatment plants are sewage treatment plants for private houses, guest houses, villages, various industrial facilities and food processing companies. We produce sewage treatment plants according to EN12566-3.

Ask our salesperson

Raitis Dambergs EN

Consultant

Mob: (+371) 28393444

E-mail: [email protected]

BIOLOGICAL WASTEWATER TREATMENT PLANTS UP TO 50 PEOPLE EQUIVALENT

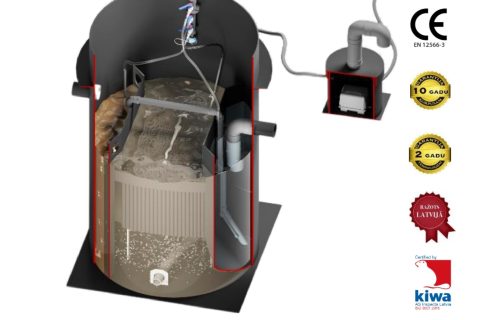

Biological treatment plant is chamber treatment plant with sedimentation, aeration, nitrification and denitrification

zones. According to applications facility can be equipped with mixers, degassing devices, lime dispensers, automatic

control and other equipment.

Operating Principles. Top – choice facilities are relatively simple and reliable. They do not need

maintenance and service contract due to higher plant capacity, reliable and durable UK compressors and German biological

units.

Installation. Installation of each unit can slightly differ, so don’t hesitate to contact our

consultant for advice, or download a standard installation scheme. If you want to get full service with the

installation, “VIRTE Tehnoloģijas” is certified for pipe and sewer construction works, or will recommend one of partners

throughout the Latvian, Scandinavia, Russia. Ask our consultant for free manual of sewer septic tank installation.

Operation and maintenance. Facility has no specific requirements for operation and maintenance.

Equipment does not emit odor, it is relatively quiet and very long-lasting, without requiring major operating costs.

Under normal circumstances, only need of a small power consumption and remove of periodic developed mud, what can be

realized by sewerage service company. If you’d like us to recommend You for the nearest service providers, contact us.

*Your assistant to find right solution – private houses, guest houses –– Matīss Lācis – tel. +371 28374336, e-pasts: [email protected]

tel. +37129620679, e-mail: [email protected]

**Your assistant to find right solution – villages, industrial facilities, the creation of high objects and food

processors -consultant Raitis Dambergs – tel. +37128393444, e-mail: [email protected]

Ask our salesperson

Raitis Dambergs EN

Consultant

Mob: (+371) 28393444

E-mail: [email protected]